The ISS’s BioFabrication Facility (BFF)—a facility developed with Techshot/Redwire—matured core collagen for developing human knee meniscus. Bioink, culture media, fixative (a substance used to preserve the tissue), and cells were transported to the ISS on NG-18 and SpX-27 missions and stored until use. Meniscus tissue was bioprinted using a bioink made of collagen types I and II, chondroitin sulfate, and mesenchymal stem cells. The print showed good shape fidelity compared to Earth-based controls but was less elastic. [4]

Meniscus tears and musculoskeletal injuries are widespread in the U.S. military, and the bioprinting study is a step toward developing a better solution on Earth and in space. The prints of tissues are grown both in microgravity and brought back to Earth to continue being analyzed and tested. [5]

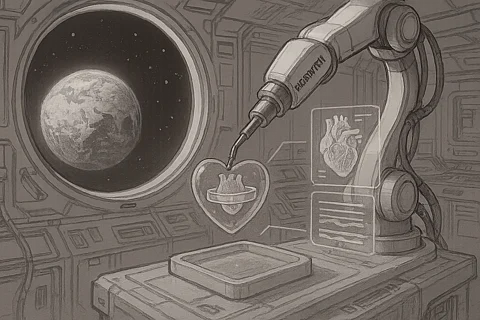

The BFF-Cardiac study examines the possibility of printing and processing a cardiac tissue sample with the help of fabrication. Heart tissue cannot regenerate; it is usually replaced by scar tissue. This research aims to develop patches and, eventually, full replacement hearts to repair damage. This would solve the existing shortage of transplant organs in the world.

In a study named Bioprint FirstAid, by the European Space Agency (ESA) and the German Space Agency (DLR), a portable handheld bioprinter was capable of preparing custom wound patches usable in space. This printer improved the wound healing process by eliminating issues of immune rejection by the patient based on the use of his or her skin cells. The device has proven to work in microgravity, and researchers are currently comparing the space-printed patches and the Earth-printed patches to inform further progress. [5]

Researchers at Stanford launched an experiment with muscle cells grown in labs that were placed in the ISS and found that space fibers were similar to those observed in sarcopenia of the aging body. They also identified promising drug therapies that would help reverse such degeneration. [6]

Driving Organizations & Collaborations